Fire Assay

Home » Our Services » Sample Analysis » Fire Assay

Fire Assay

Home » Our Services » Sample Analysis » Fire Assay

Fire Assay

Fire assaying is the classical technique by which precious metals are quantified. Pulped samples are mixed with a flux and heated in a furnace at over 1000°C. The flux will react under the intense heat to form a dense, corrosive melt into which the precious metals dissolve, and a light, glassy component which floats over the top.

Once the reaction is complete, the melt is removed from the furnace and poured into a conical mold, where the different components stratify and can be separated. The glassy component is discarded and the precious metals containing component is sent for analysis.

The two flux types used at Paragon are litharge and nickel sulfide. In a litharge-based flux, the fusion reaction produces liquid lead metal which percolates through the sample, dissolving the precious metals and collecting at the bottom. In a nickel-based flux the components react to form a nickel sulfide matte which serves as the collector.

Paragon offers an array of different fire assay services which allow for determination of gold, silver and platinum group metals at various grades.

Our Process

Once preparation is complete, samples can be analyzed for metals content. Most samples will follow one of two analytical processes: wet geochemistry for a broad spectrum of elements, or fire assay for precious metals, both of which are described here.

Lead Flux Mixture: Combines pulps with a lead flux mixture and fuse at ~1150 C to break down the chemical bonds within the sample, collecting the precious metals and allowing their quantification.

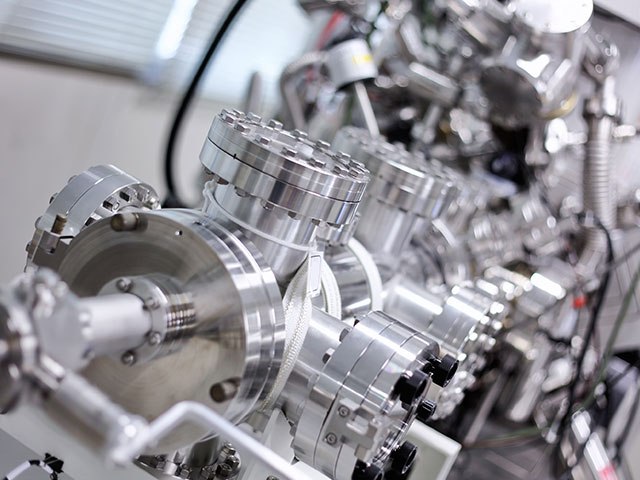

Furnace: Fusion furnace can fire 84 pots at a time. Lead fumes from the process are captured within the baghouse filter. Cupellation takes place at ~1000 C where fused buttons oxidize and are absorbed into cupels leaving behind the precious metals.

Gold Beads: From the fire assay process, the resultant precious metal beads are quantified by one of two ways: gravimetrically or through AA/ICP. The gravimetric process involves parting away any silver and weighing the resultant gold flake. AA/ICP involves digesting the bead in aqua regia and analyzing the solution by an AA or ICP instrument.

Pre-Operations Checks

Reagents, fluxes, crucibles and cupels: Vendor prepared flux batches are tested for gold before client samples are analyzed. Results from 6 tests are determined with method Au-OES30 that has a detection limit of 0.001 ppm. Tests also confirm crucible and cupel cleanliness. Reused crucibles are either cleaned by firing them with a cleaning mixture, or by classifying them per their prior assay’s gold concentration.

Equipment: Fusion furnaces are made by Furnace Industries and the cupellation furnaces are made by Pyradia. All furnaces utilized by Paragon have dual pyrometers that must remain within tolerance or will indicate a problem code. Pyrometers must be replaced every 12 months.

Processing Checks

Samples are visually and chemically prescreened for flux suitability. Before adding flux to samples, sample color and chemical reactivity is evaluated. Reactivity is measured with a droplet of nitric acid on the sample which will indicate which flux amendment to add.

A furnace load is 84 samples or two racks of 42. Furnace temperatures are examined 15 minutes after sample loading—the fusion time upon which the furnaces’ temperature should recover to its maximum temp.

Post-fusion indicators are many, and often visually apparent. Fusion slag clarity, color and brittleness is evaluated, along with the lead buttons’ weights and malleableness.

Post cupellation indicators are found in the residue left on the cupels from the flux lead or other metals, cupel color, and prill weight, color and shininess.

Fire Assay Prill Digestion

Pre-Operations Checks

Acid quality: Perform validation tests on new HCL and HNO3 acid purchases by performing six sample digestions without prills and analyzing by ICP-OES. The results should be 0.001 ppm or lower.

Equipment: Hot plate temperature is measured with an approved thermometer and verified before sample digestion. Acid dispensers are checked daily by dispensing every 5 times and comparing the dispensed weights to the calculated target weights. The 8 ml bulking dispenser must be within 0.5% of the target weight, and the other dispensers within 2%.

Processing Checks

Fire assay cupels’ copper stain indicators are compared to the fire assay worksheets for accuracy. Any deviations are documented and noted in LIMS. For quality control, the copper checking process will not be performed by the fire assay department—it must be done by the digestion techs. When paperwork properly reflects cupel staining, sample sequences are correct through the fire assay process. Prills in racks of 42 will be transferred to the 60-position test tube racks. The digester will complete a rack form for each rack that indicates the jobs and samples contained therein.

Paragon Geochemical is a full service assay lab in Sparks Nevada.

Weighing Fire Assay Aliquots

Pre-Operations Checks

Equipment: aliquot scales are serviced and tested for performance every 12 months by an ISO certified professional. At the beginning of each workday, scales are checked for level using the built-in level-indicator bubble, then weighing and calibrating to certified weights of 0.5, 1, 10, 20 and 50 grams.

Processing Checks

Sample pulps are weighed into racks of 42 with the aid of computer tracking. Client sample weights are captured and saved if weights fall within 2 grams of the fire assay method weight. Weighing progress is indicated by a computer monitor that reports the samples already weighed, the sample being weighed, and the remaining samples to complete the rack. In addition, the weighing process has several quality checks through bar code scanning that ensure that the correct sample is being weighed, and that the weighed aliquot is physically placed in the proper location of the rack. Weighing also entails adding copper to computer-chosen aliquots in order to verify sample sequences through the fire assay process. Aliquots requiring copper are indicated on the computer monitor that also shows the captured weight of the copper. Three coppers will be added to each group of seven weighed aliquots.

Certified and Internal Reference Materials

One certified reference standard (CRM) and one internal reference standard (IRM) is analyzed for each rack of 42 positions. CRMs are weighed at the client-mandated weight; IRMs are weighed at varying weights, providing a spectrum of gold concentrations, from near baseline to the upper limit of reporting. Each rack also has a duplicate sample and a blank, resulting in 38 client samples per rack of 42.

Paragon Geochemical is located in Sparks, Nevada and is a mid-size provider of commercial assay lab services to the mining and exploration industries. Paragon is committed to providing assay services that meet all industry and regulatory standards of best practice while consistently beating industry expectations for turnaround time and customer service.

Dependable Quality. Rapid Turnaround. Unmatched Value.

Paragon’s core conviction is that to provide value, results of unquestionable quality must be reported rapidly for informed decision making. Our service offerings include a wide range of analytical techniques to suit the needs of the mining industry.