PhotonAssay™

Home » Our Services » Sample Analysis » PhotonAssay™

PhotonAssay™

Home » Our Services » Sample Analysis » PhotonAssay™

Gold, Silver & Copper by PhotonAssay™

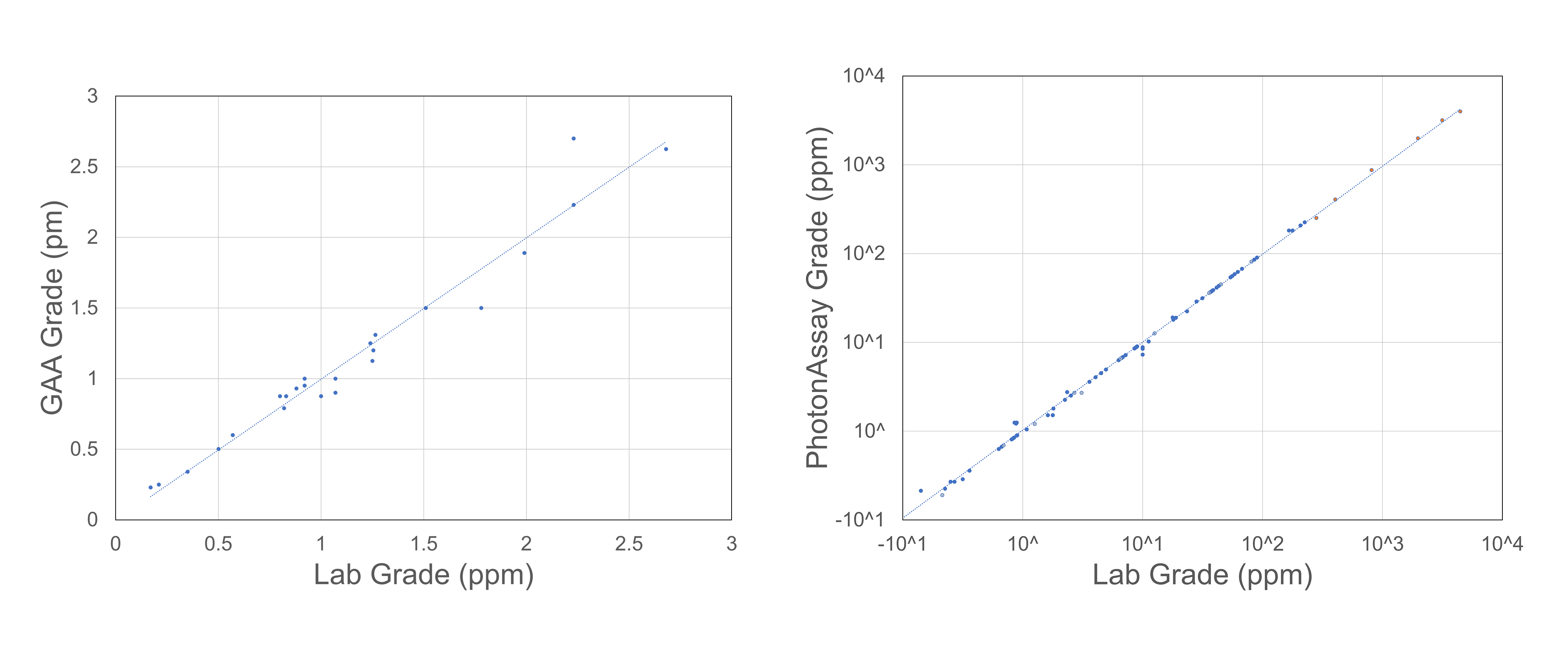

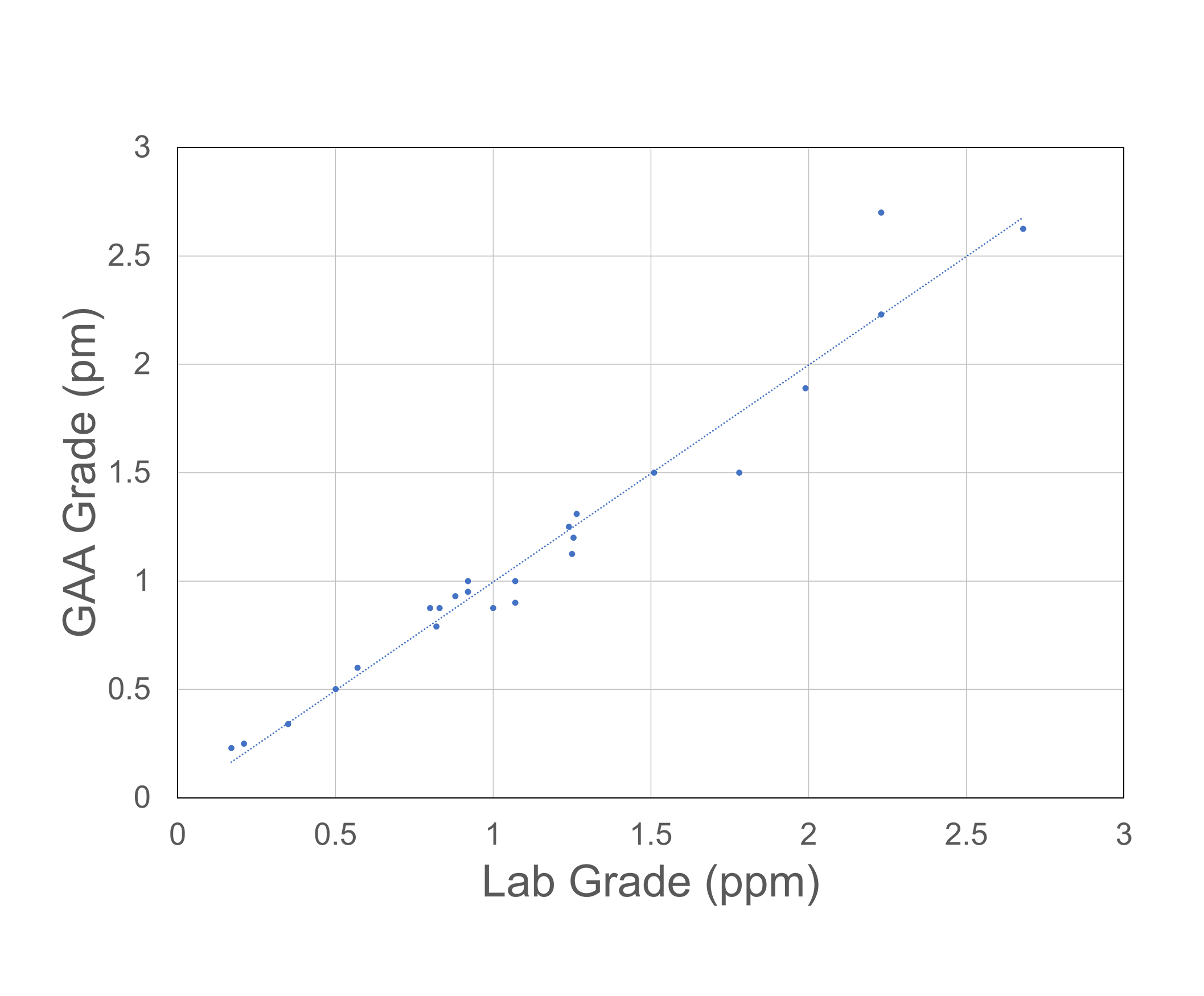

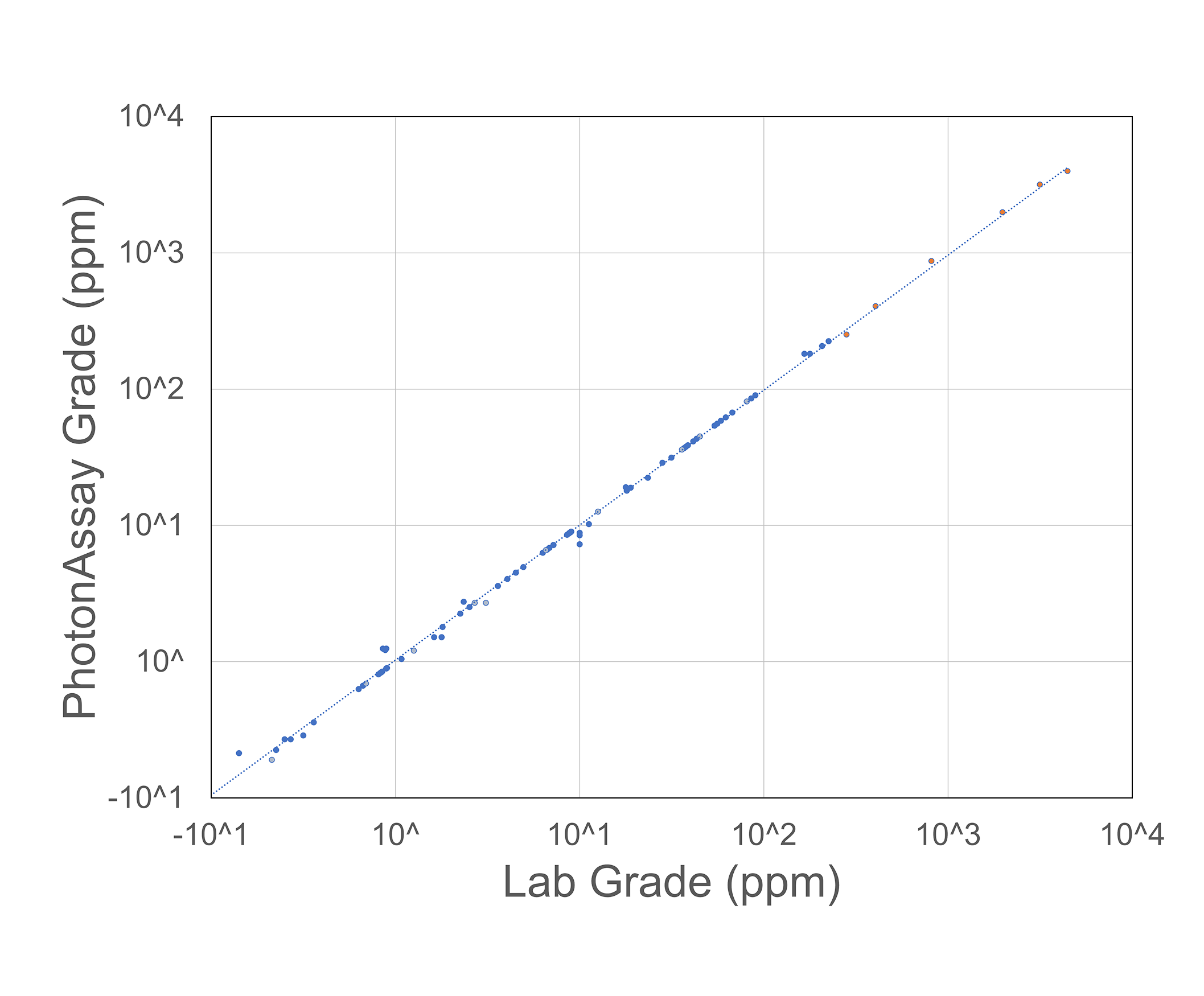

PhotonAssay™ is a fast, accurate, non-destructive process to determine gold, silver and copper in geological and process samples.

The technique uses gamma ray activation to induce nuclear transitions in the elements of interest, which leads to photon emissions with highly characteristic energies.

PhotonAssay™ can be performed on coarsely crushed material, allowing for simplified prep protocols. A large assay charge of approximately 500g is introduced to the instrument, improving representativeness of the sample. The time required from sample introduction to results acquisition can be as little as 3 minutes.

After analysis, the entire assay charge is returned intact and can be submitted for subsequent analyses such as geochemistry, cyanidation, metallurgical testing, environmental testing, etc. or retained for future verification.

Unlike traditional assay techniques, PhotonAssay™ does not use acids nor other hazardous reagents, does not generate lead fumes or solid waste, reduces manual handling and cuts the per-sample carbon footprint by up to half.

Traditional Fire Assay |

|---|

| Fully dry sample |

| Prepare sample (crush/Grind) |

| Divide into 25-50g aliquots |

| Prepare fusion samples (mix with flux/litharge) |

| Fusion: fire sample at 1000-1200 degrees centigrade |

| Separate lead button from slag |

| Cupeling: re-fire button to remove lead |

| Dissolve remaining metal in concentrated acid |

| Analyze resulting solution via AAS / ICPMS |

New PhotonAssay™ |

|---|

| Optionally-dry sample |

| Crush sample to nominal 2mm or pulverize, then load into barcoded jar |

| Place jar on to automated conveyer for quantitative analysis in less than 3 minutes |

| Fire Assay | PhotonAssay™ | |

|---|---|---|

| Time per sample | ~3-4 hours | <3 minutes |

| Sample size | 10-50 grams | 350-500 grams |

| CO2 per sample | 0.91 kg | 0.455 kg |

| Hazardous waste per sample | 0.31 kg | 0 kg |

| Energy use per sample | ~1.3 kWh | ~0.65 kWh |

| Automation | No | Yes |

Dependable Quality. Rapid Turnaround. Unmatched Value.

Paragon’s core conviction is that to provide value, results of unquestionable quality must be reported rapidly for informed decision making. Our service offerings include a wide range of analytical techniques to suit the needs of the mining industry.